Many industrial food companies work, or want to work, with frozen products in the production process.

Whether it is meat or fish or even vegetables or fruit, cutting up frozen food before processing avoids contamination and loss of nutrients, it ensures the freshness of the product and reduces cooling costs for the user.

Our flakers are equipped with a specially designed stainless steel knife roller that rotates at two (2) speeds and cuts the food product into thin flakes. This significantly reduces processing time and improves the quality of the final product.

antec offers a range of frozen block shredders/ flakers with varying capacities, the most compact model the Lakidis FR-100 offers a maximum capacity of 1500 kg/hour for a product with temperatures from 15°C to -18°C and the largest model the N&N FL-660 offers a maximum capacity of 8000 kg/hour for a product with temperatures up to -30°C. In between, the range offers 3 other types of flakers; FR-300, FL-330, FL-440 and a guillotine the GN-400.

The FR-300, FL-440, FL-660 are equipped with a pneumatic system, which is responsible for feeding the frozen blocks into the knife roll, and during operation all required special safety systems are applied.

The DC Breaking System, is the safety system responsible for the mechanical and electrical braking of the machine if the emergency stop is pressed or safety devices are interrupted. The machines are technically equipped with various sensors;

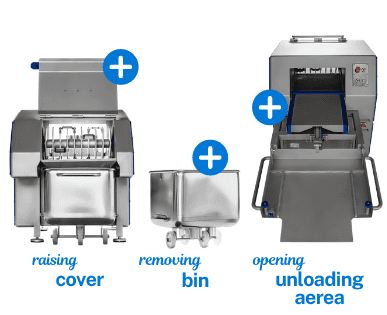

- The cover over the knife roll. When open, the machine does not run.

- Checking the presence of a standard carriage. If the standard carriage is not present, the machine will not run.

- Pneumatic system. If the pneumatic pressure system is open for the cleaning position, the machine does not run.

Our frozen blocks reducers / flakers meet the daily needs of a wide range of industries such as the meat, fish and dairy industries, but also for the production of juices from frozen fruit blocks, for cutting frozen vegetables and for cosmetic products.

Can we offer you advice and a specialised proposal tailored to the needs of your production process? Please contact us directly or fill in the contact form and we will get back to you as soon as possible.